Exxelia Ohmcraft's cutting-edge resistors redefining reliability in the aerospace industry

Empowering Space Exploration: Unveiling the Cutting-Edge Exxelia Ohmcraft Resistors

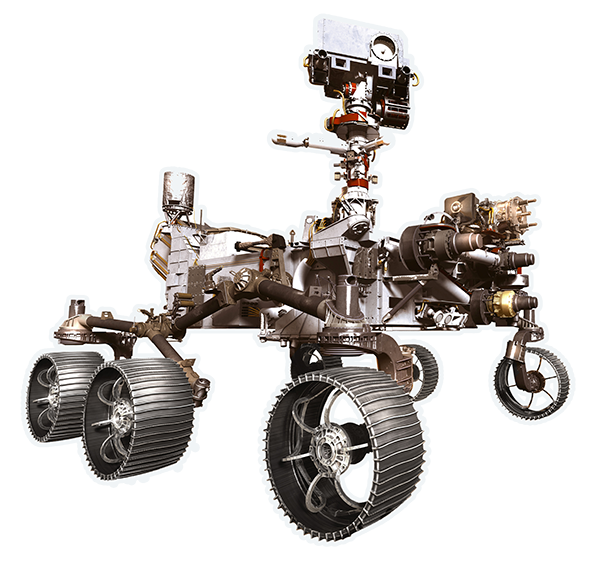

Exxelia Ohmcraft provides designers of space instrumentation with resistors that are the foundation for building robust power supplies, sensors and imaging equipment. Exxelia Ohmcraft products have helped push forward scientific advancements in mass spectrometry, image intensifiers, X-Ray sources and spectroscopic analysis. We provide standard and custom products to many market leaders with the reliability that makes Exxelia Ohmcraft the resistor of choice for such critical scientific space applications.

Exxelia Ohmcraft provides designers of space instrumentation with resistors that are the foundation for building robust power supplies, sensors and imaging equipment. Exxelia Ohmcraft products have helped push forward scientific advancements in mass spectrometry, image intensifiers, X-Ray sources and spectroscopic analysis. We provide standard and custom products to many market leaders with the reliability that makes Exxelia Ohmcraft the resistor of choice for such critical scientific space applications.

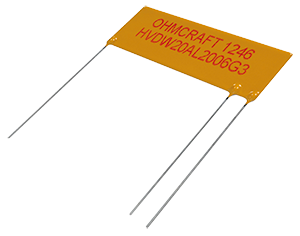

Our unique Micropen precision printing technology produces ultra-stable resistors with exceptional reliability that are perfectly suited for space flight applications. For over 20 years, Exxelia Ohmcraft has been designing resistors used in instruments on various spacecrafts. Our resistors enable the analytical equipment designed for strategic science missions which creates the space technology that explores outer space.

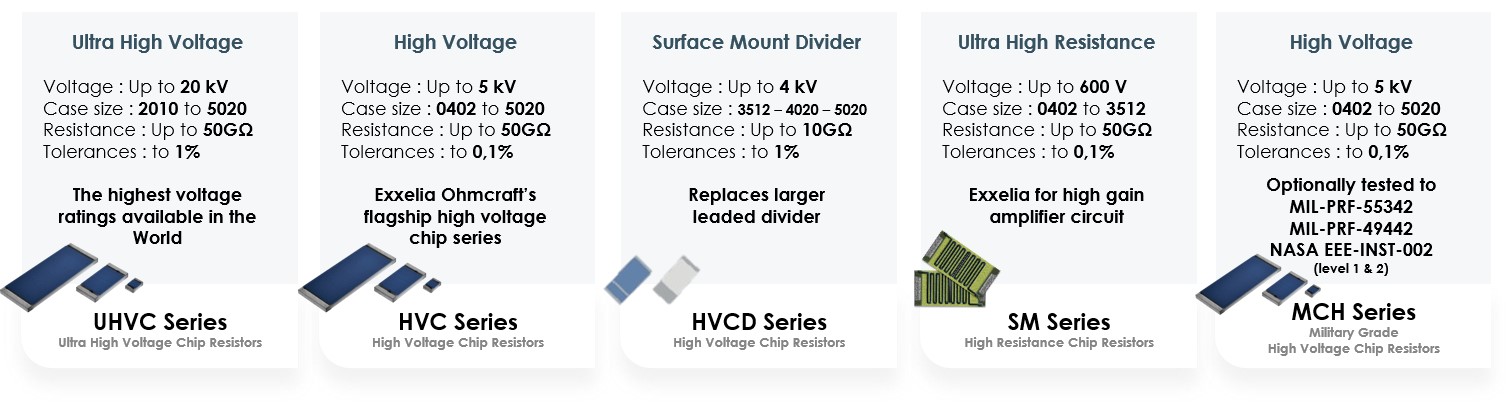

Exxelia Ohmcraft technology produces a superior resistor. The combination of our longer serpentine pattern and high-aspect ratio gives our resistors unmatched design flexibility, linearity, stability and low noise capability as well as:

Ultra High Voltages up to 60 kV

Ultra High Voltages up to 60 kV

Extremely tight tolerances to 0.1%

Very low TCR with extended temperature range

Very low noise / Very low VCR

Ultra-high stability

Custom designs for Space applications

Exxelia Ohmcraft ability to design and deliver custom resistors is essential for space instrumentation designers. Our engineers work closely with you to design resistors that match your exact specifications.

Surface-mount resistors, dividers and networks

Extensive experience designing custom resistors and supporting source

control drawings (SCD) for existing and new designs

Engineering Models

Flight Models

Exxelia Ohmcraft can perform Lot Acceptance Testing (LAT) on our resistor products using a number of Space and Military Specifications, including:

NASA EEE-INST-002 Level 1, Level 2 or Level 3

MIL-PRF-55342, MIL-PRF-49462 and MIL-PRF-83401

MIL-STD-202

ESCC 4001 (ESA/SSC 4001)

Our expertise in designing for military applications spans across a spectrum of products, each contributing significantly to advancing military capabilities:

Scientific Instrumentation

Scientific Instrumentation

Products: MCH, HVR, HVD, HVA and Custom designs

Applications:

Mass Spectrometers

Ion Mobility Spectrometers

Test Equipment

Signal Generators

Chemical / Mineral Sample

Analysis

Instrumentation Power Supplies

Instrumentation Power Supplies

Products: MCH, HVR, HVD, HVA and Custom designs

Applications:

High Voltage Custom Power Supplies

Vision Systems

Vision Systems

Products: MCH, HVR, HVD, HVA and Custom designs

Applications:

Image Intensifier Circuits

Optical Spectrometers

Photomultipliers

Exxelia Ohmcraft is the leader in high performance resistor design and manufacturing. Our proprietary Micropen precision printing technology enables

superior precision thick-film resistors. Exxelia Ohmcraft can meet the most challenging space instrument specifications for high voltage and high value resistors.

Exxelia Ohmcraft’s sister division, Exxelia Micropen Medical is at the forefront of medical device product development, providing design engineers with unique insights on conceiving and implementing new designs and features.