A “Game Changer” Rectangular Aluminum Electrolytic Capacitor, Called Cubisic SLP

Cubisic SLP is the new rectangular aluminum electrolytic capacitor from EXXELIA, a world leader in manufacturing and designing capacitors. Their products are known for their high performance and reliability, which has made them the choice of many of the world's leading avionics engineering companies. However, they were looking for a new, more reliable capacitor that could withstand even greater vibration and altitude than any previous capacitor. They needed a stronger, more reliable product with a life expectancy that matched the customers' projects.

Product description :

Cubisic SLP is among the industry's first aluminum electrolytic capacitors designed with flat technology. The result is a lighter, smaller rectangular shape with increased surface area, which improves its capacity. As a result, it can accommodate more energy at almost any altitude or vibration level.

This makes Cubisic SLP ideal for applications where added durability is required, such as cockpits and power generation functions on aircrafts, along with being well-suited for radars and laser systems in up to 50G vibration conditions and 92K feet altitude resistance.

✅ Low profile printed circuit mounting

✅ Possible mounting with 45 x 12 bracket (A691057)

✅ Possible thermal dissipation per conduction through a lower and upper surface

✅ Switch mode power supplies, impulse current

✅ Withstands more than 92,000 feet altitude

✅ Sleeve optional

Cubisic SLP comes in three sizes, is made with high-quality aluminum foil and impregnate with electrolyte. It has 2 terminals: anode, cathode.

What makes Cubisic SLP so different?

An example of one of the advantages of this technology is that designing a capacitor with a traditional cylindrical shape, means that 2/3 of its volume is empty, compared to this new flat design. As a result, more capacitors are packed into the same volume, thus increasing the density.

What’s a Rectangular Aluminum electrolytic capacitor, and why is that important?

What’s, a Rectangular Aluminum electrolytic capacitor :

In short (no pun intended), a rectangular electrolytic capacitor is one of those components that keeps your electronics running safely, your ship floating, and your aircraft operating properly.

A Rectangular electrolytic capacitor is a component that essentially stores electrical energy in the form of an ‘electrolyte’. It’s made up of three layers: two aluminum sheets separated by an electrolyte solution and encased in a steel or porcelain container. And as the name implies, it’s shaped like a rectangle. It's widely used in different industries because of its reliable and cost-effective protection, which makes it the go-to component for many commercial, industrial, and aerospace uses. Rectangular aluminum electrolytic capacitors are mostly used in military aircrafts, missiles, and nautical transportation, as well as space navigation systems. In these applications, reliability is crucial for the safety of millions of people, so it is essential to choose a reliable product that offers high performance and quality.

So if you find yourself with any of those use cases and/or engineering projects on your hands that require high performance and quality under extreme environments, look no further than this capacitor!

Why is that important?

As an example, when a military fighter jet accelerates, it can experience up to three times the force of gravity. While this is an impressive feat, consider what it does to the components in the vehicle. One such component is a capacitor. While it might seem like just a small piece of circuitry, capacitors are responsible for a variety of functions in your fighter jet, including:

> Powering the radar antenna

> Controlling engine performance

> Controlling flight-related functions like fuel injection and landing gear operation

This is because of the way they deal with heat buildup, which is an issue with capacitors in high-performance vehicles, especially on aircrafts where rapid acceleration can cause significant damage to any component.

That's helpful in the cockpit, where the controls are exposed to this kind of force; a control that has to withstand up to three times the force of gravity will last longer than one that isn't designed for this. In other places on a military jet—such as power generation functions—the same principle applies: if something is going to be exposed to extreme forces (like vibration or acceleration), it needs to be strong enough not to break easily. That's why these capacitors are a great choice: they can handle extreme conditions without losing their effectiveness over time.

That's why Exxelia takes the time to test every single capacitor we sell to our customers.

How does its ability to withstand varying vibration levels and altitudes make a difference to the aerospace industry?

What makes a rectangular aluminum electrolytic capacitor so effective for aerospace companies? The answer: They're made from high-quality material—pure and simple. But the difference between standard capacitors and those for the aerospace industry goes far beyond that. For the aerospace industry, the ideal capacitor would endure extreme temperatures, have a wide range of voltage tolerances, and withstand varying vibration levels, all while maintaining its effectiveness at an altitude of 19,000 meters—which is where Cubisic SLP comes in. As an electrolytic capacitor with an expanded operating temperature range and a very high resistance against vibration and altitude changes, this product has been able to make a huge difference in how well aircrafts can stay in control. Not only does it help prevent power outages, but also it helps avionics to stay functional when they are subjected to drastically changing conditions. Cubisic SLP capacitors are designed to handle extreme environments, which makes them incredibly versatile—and incredibly useful. From aeronautics to medicine, these capacitors can help your projects meet just about any challenges.

Where can I find out more about EXXELIA’s Cubisic SLP range?

Radial aluminum electrolytic capacitors cubisic SLP

Radial aluminum electrolytic capacitors cubisic HTLP

Radial aluminum electrolytic capacitors alsic 145 20g

Radial aluminum electrolytic capacitors alsic 20g

Radial aluminum electrolytic capacitors cubisic lp

Radial aluminum electrolytic capacitors cubisic

TECHNICAL PAPERS (Electrical characterization of cubisic SLP capacitors)

DOWNLOAD DATASHEET

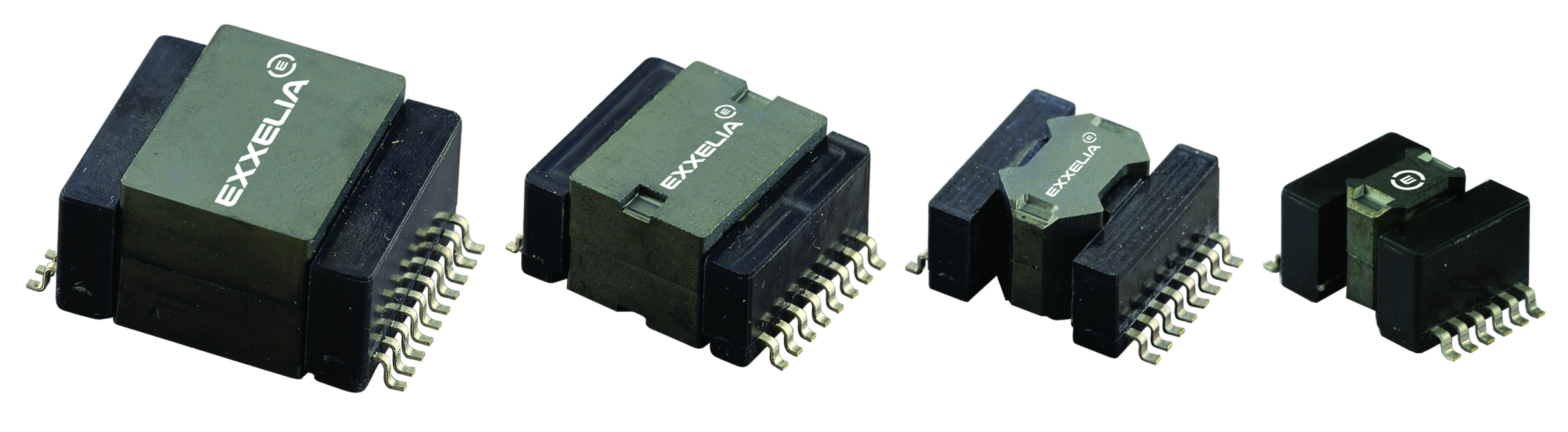

Exxelia designed CCM technology to respond to the growing interest of electronic engineers for inductors and transformers with multiple outputs, high power density and reduced footprint. Qualified for aeronautic and space applications, the CCM product line features terrific robustness. The monolithic design provides high mechanical performance, proven by the successfully testing in accordance with MIL-STD-202 (methods 213 and 204). The series offers five different sizes, allowing optimized component design in a pick-and-place surface mount (SMD) package. Through-hole (TH) packages are also available upon request. The CCM series is particularly flexible with a number of pins options available, from 2×6 pins for the smallest package, up to 2×10. CCM transformers and inductors can operate over a wide temperature range with a minimal temperature of -55° C. The standard thermal grade of the technology is 140° C. Thanks to the technology design, the thermal resistance is 30% lower than standard industrial components. The epoxy molding protecting the winding ensures a lower temperature gradient and a better heat dissipation. Each unit is thoroughly tested with a dielectric withstanding strength of 1,500 VAC. Component materials meet UL 94-V0 rating.

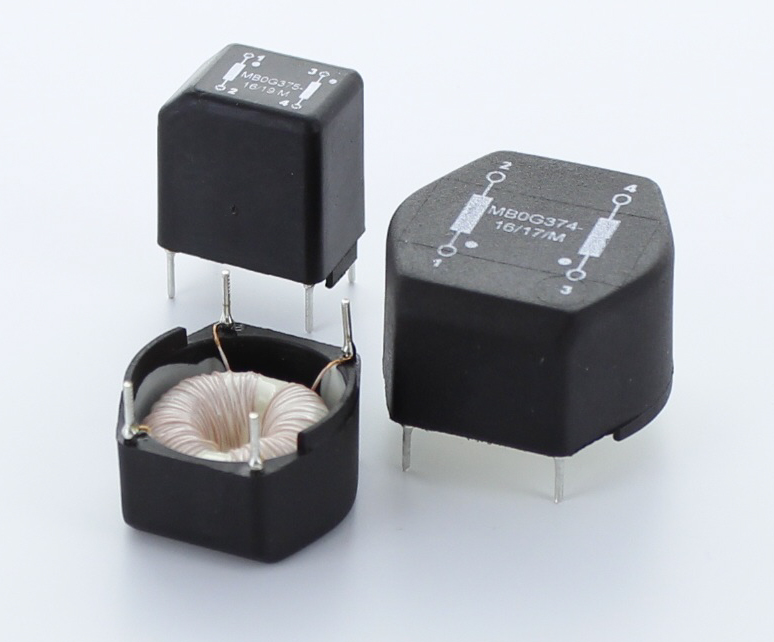

Exxelia designed CCM technology to respond to the growing interest of electronic engineers for inductors and transformers with multiple outputs, high power density and reduced footprint. Qualified for aeronautic and space applications, the CCM product line features terrific robustness. The monolithic design provides high mechanical performance, proven by the successfully testing in accordance with MIL-STD-202 (methods 213 and 204). The series offers five different sizes, allowing optimized component design in a pick-and-place surface mount (SMD) package. Through-hole (TH) packages are also available upon request. The CCM series is particularly flexible with a number of pins options available, from 2×6 pins for the smallest package, up to 2×10. CCM transformers and inductors can operate over a wide temperature range with a minimal temperature of -55° C. The standard thermal grade of the technology is 140° C. Thanks to the technology design, the thermal resistance is 30% lower than standard industrial components. The epoxy molding protecting the winding ensures a lower temperature gradient and a better heat dissipation. Each unit is thoroughly tested with a dielectric withstanding strength of 1,500 VAC. Component materials meet UL 94-V0 rating. Exxelia designed this extensive and cost-effective range to be an easy commercial (COTS) solution for aerospace, defense, and other high-reliability applications. The TCM series is available in a through-hole package for horizontal or vertical mounting. TCM chokes are offered with inductances from 0.7 mH to 47 mH under rated currents from 0.3 to 4.0 A. Each unit is thoroughly tested with a dielectric withstanding strength of 1,500 VAC. Excellent thermal properties allow the series to operate from -55° C to +125° C. The high mechanical performance of the component materials (all meeting to UL94 V0 rating) makes TCM a perfect fit for aviation, defense and transportation industries.

Exxelia designed this extensive and cost-effective range to be an easy commercial (COTS) solution for aerospace, defense, and other high-reliability applications. The TCM series is available in a through-hole package for horizontal or vertical mounting. TCM chokes are offered with inductances from 0.7 mH to 47 mH under rated currents from 0.3 to 4.0 A. Each unit is thoroughly tested with a dielectric withstanding strength of 1,500 VAC. Excellent thermal properties allow the series to operate from -55° C to +125° C. The high mechanical performance of the component materials (all meeting to UL94 V0 rating) makes TCM a perfect fit for aviation, defense and transportation industries.