Sub-assembly

Internationally acknowledged as a manufacturer of leading-edge electronic components, Exxelia can also deploy its unique know-how in the electromechanical design of assembly modules to offer its customers global solutions.

We also have the capability to adapt to all types of casing, connections and fixturing materials; flexibility is one of our watchwords.

The Design and Development departments at Exxelia focus on offering modules and sub-assemblies that embody increasingly complex, high-performance functions to optimize and simplify integration for our customers.

our recent projetcs have included:

-

Rotating systems

combining slip rings, fiber optic rotating joints, hyperfrequency rotating joints, and optical encoders -

Modules

with built-in capacitors -

Voltage multipliers

(e.g.: photomultiplier applications), from single components to modules -

Filters (EMC and signals)

by integration, molding or by associating selfs and capacitors in customer-specific volumes and connections -

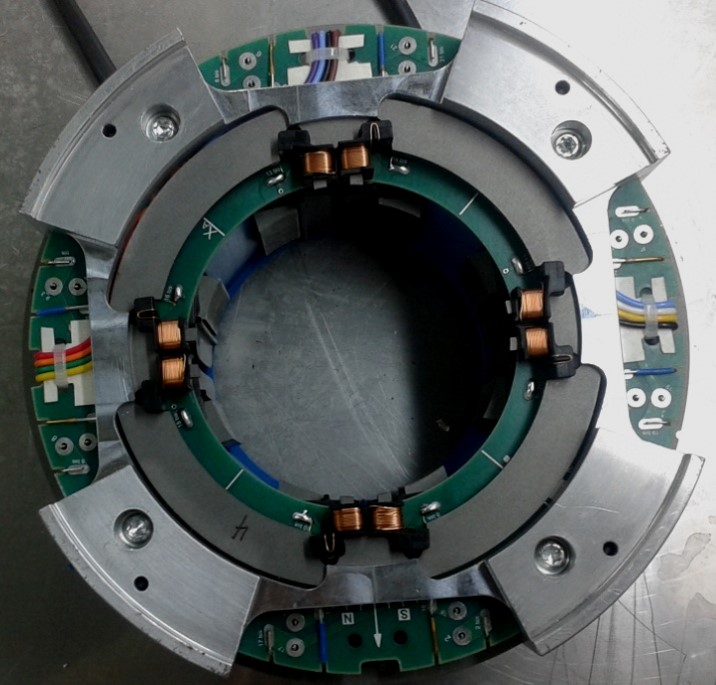

Electromagnet elements

integrated into machined cast parts, with added mechanisms and cables to deliver a complete electromagnet; stator elements with insertion and clamping in a machined mechanical body -

Assemblies

with micromechanical, electrotechnical, electronic technologies, cables and connectors made to customer specifications Integrated

electronic boards

Precision machining

The Precision Mechanics division of Exxelia specializes in the machining of complex, high-precision parts, from prototype to medium-scale production runs. We have equipment to machine all types of materials: special steels, aluminum alloys, inconel, titanium, composites.

Our machines:

NC machining centers

NC lathes

NC grinders

4 and 5 axis CNC milling centers

3 axis CNC turning

tri dimensional measurement control

Hydraulic test equipment up to 500 bars

Our specialities:

-

Manufacturer

of prototypes, small and medium scale production runs (milling, turning, trimming, grinding, fettling, EDM, drilling) in the fields of aeronautics, space, defense, the automotive industry, food processing and pharmaceuticals, nuclear energy -

Spare parts manufacture

for aeronautics, production equipment, space -

Modules, assemblies and tests

on mechanical and hydraulic assemblies -

Maintenance

of hydraulic and electromechanical equipment (disassembly, expertise, repairs, assembly, testing) -

Inspections and checks:

dimensional, non-destructive, traceability, conformity certification -

Procurement:

molded parts, dies, raw materials, components